Purdue University Northwest students and faculty are doing their part to help those on the frontline assisting people during the crisis created by the COVID-19 outbreak.

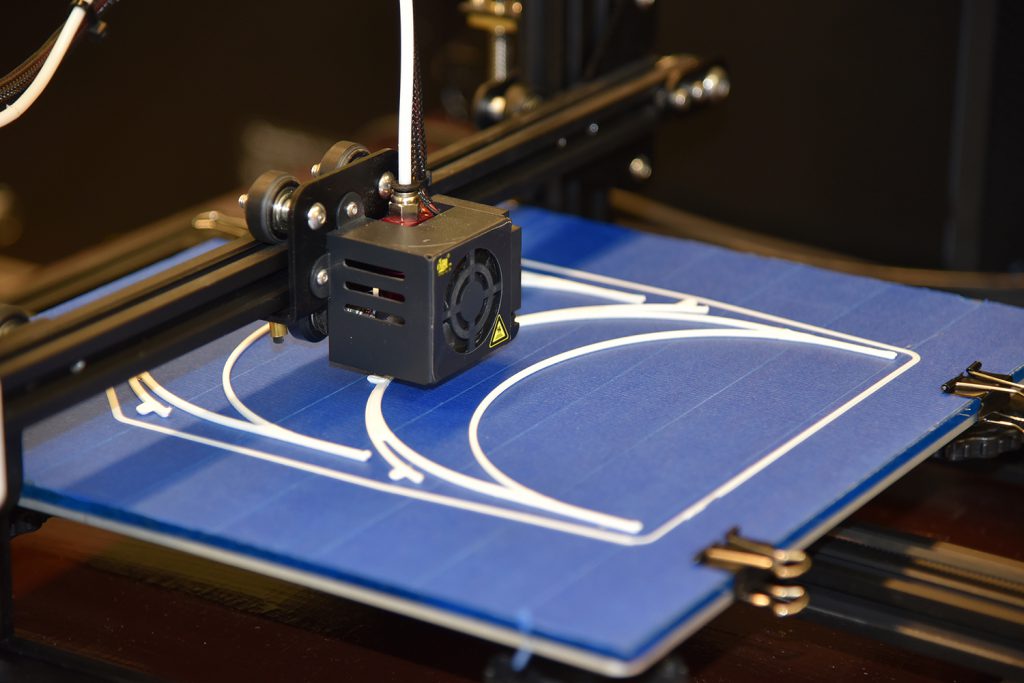

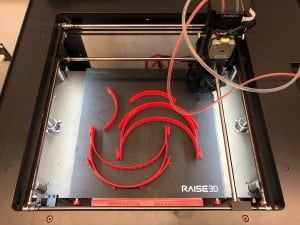

Students from PNW’s College of Technology, with support from their faculty and staff mentors, are putting six of the university’s 3D printers to work to produce pieces of face shields. The pieces are used to make face shields or personal protective equipment, worn by emergency medical technicians and other first responders when treating patients.

The students, while practicing social distancing, networked the printers on PNW’s Hammond and Westville campuses, and were able to monitor production remotely.

The face shield parts will be donated to InHealth, a Valparaiso-based ambulance service, which operates throughout Northwest Indiana and has sent crews to respond to the crisis in New York.

“I am delighted that the college of technology faculty, staff and students can help our local hospitals and first responders,” said Mohammad Zahraee, interim dean of PNW’s College of Technology. “I want to express my gratitude to our College of Technology students Zachary Szymanek, Jacob Powers, Nathan Lewis and Stephen Gries for their tireless efforts in producing as many personal protective equipment components as possible. Not only are they helping with this noble cause, they also are learning a lot about engineering principles as they research and implement ways to increase production with our existing equipment.”

InHealth will use the PNW-produced parts, along with straps and plastic shields from another source, to assemble face shields that will be distributed to Northwest Indiana health care providers, including front-line staff at area hospitals. The PNW College of Nursing and the Northwest Indiana Area Health Education Center also are contributing financial support to the effort.

“We at InHealth greatly appreciate the community partnership of Purdue Northwest and other Northwest Indiana institutions that have collectively used about 20 of their own 3D printers so far, plus volunteers, to help supply parts for personal protective equipment for frontline healthcare workers,” said Ron Donahue, chief executive officer of InHealth. “Any institution or company that has 3D printers to loan to the effort is welcome to contact me as we continue to work together to battle this widespread disease.”

Zahraee said the PNW School of Engineering made it possible to double production by making its 3D printers available for the volunteer effort.